Another Stockout? Stop Guessing Your Inventory Needs. Master 3 Scientific Safety Stock Formulas Today.

From guessing to science: Master 3 safety stock formulas to solve inventory anxiety and balance stockout risks.

This guide will take you from the 'art' of guessing to the 'science' of data-driven inventory planning.

Another Stockout? Stop Guessing Your Inventory Needs. Master 3 Scientific Safety Stock Formulas Today.

"Hey, where's my order? Why hasn't it shipped yet?"

It's Monday morning. You open your seller dashboard as usual, and your heart sinks. That best-selling product you were counting on is glaring back at you with a bold, red "Out of Stock." Meanwhile, your ads are still burning cash, customer complaints are flooding your inbox, and your supplier says the next shipment won't arrive for at least 15 days.

At that moment, you're losing more than just a few hundred sales. You're losing customer trust and your product's precious momentum.

Sound familiar?

We all hate stockouts, but we're equally terrified of overstocking—tying up cash flow and choking our warehouse with products that don't sell. So, is there a way to walk the tightrope between these two beasts without falling?

Absolutely. That tightrope is called Safety Stock.

This article will guide you from the "art" of guessing to the "science" of data-driven inventory planning, helping you conquer your inventory anxiety once and for all.

What Exactly is Safety Stock? (It's Not as Scary as It Sounds)

Don't let the technical terms fool you. The concept is incredibly simple.

Think of safety stock as the reserve fuel tank in your car.

- The fuel you put in regularly (your Cycle Stock) is for your planned journey from Point A to Point B.

- The reserve tank (Safety Stock) is for two kinds of unexpected events:

- You hit a massive traffic jam, and your fuel consumption is higher than expected (Demand Variability).

- The next gas station is further away than you thought, or it's temporarily closed (Lead Time Variability).

So, safety stock isn't your day-to-day inventory. It's the buffer you keep on hand for the "what ifs," and its value comes down to three things:

- Preventing Lost Sales: Capturing every order you rightfully deserve.

- Boosting Customer Experience: Making your store feel reliable and always in stock.

- Stabilizing Operations: Freeing you from the daily chaos of emergency reorders.

A Step-by-Step Guide to Calculating Safety Stock (From Beginner to Pro)

Here are three tiers of safety stock formulas, progressing from simple to precise. There's a method here for everyone.

Level 1: The Basic Formula (Your Reliable Starting Point)

This formula is perfect for new sellers who have limited data and need a quick, conservative estimate. It calculates the difference between the worst-case and average-case scenarios.

The Formula:

Safety Stock = (Max Daily Sales × Max Lead Time) – (Average Daily Sales × Average Lead Time)

Let's use an example:

You sell a popular t-shirt, and your data from the last month shows:

- Average daily sales: 50 units

- Maximum daily sales (on your best day): 120 units

- Average supplier lead time: 10 days

- Maximum supplier lead time (when things went wrong): 15 days

Plugging it in:

Safety Stock = (120 units × 15 days) – (50 units × 10 days)

Safety Stock = 1800 – 500 = 1300 units

Conclusion: To cover a perfect storm of peak demand and maximum shipping delays, you'd need an extra 1,300 t-shirts in reserve.

Feeling like that's a bit much to calculate by hand? Don't worry, I've built a small tool for you at the end of this article that does the math instantly.

Level 2: The Fixed Days' Supply Method (Simple & Strategic)

This approach relies less on complex math and more on your strategic judgment. It's simple and highly effective.

The Formula:

Safety Stock = Average Daily Sales × Desired Safety Days

How do you determine your "Safety Days"?

- For core best-sellers or products with unreliable suppliers: Aim for a longer period, like 14-21 days.

- For stable, everyday products: 7-14 days is usually sufficient.

- For long-tail or clearance items: You might want 0-7 days, or even none at all.

Example:

For that same t-shirt with 50 average daily sales, you consider it a core product with a slightly unpredictable supply chain. You decide on 14 safety days.

Safety Stock = 50 units/day × 14 days = 700 units

This method allows you to infuse your own business experience and strategy directly into your inventory model.

Level 3: The Statistical Formula (The Pro's Choice)

Ready to level up? We're now bringing in statistics to make your inventory decisions incredibly precise. This is for sellers who want to be truly data-driven.

Key Concept: Service Level

This represents the probability that you won't stock out during a replenishment cycle. The higher the service level, the more safety stock you need. Each service level corresponds to a fixed Z-score.

| Service Level | Z-score | What It Means |

|---|---|---|

| 90% | 1.28 | You might stock out in ~10 out of 100 cycles. |

| 95% | 1.65 | (Industry Standard) You might stock out in ~5 cycles. |

| 99% | 2.33 | You almost never stock out, but inventory costs are high. |

The Ultimate Formula: Accounting for All Variables

This formula considers both demand variability and lead time variability.

Safety Stock = Z-score × Standard Deviation of Demand During Lead Time (σLTD)

I know, "Standard Deviation of Demand During Lead Time" sounds intimidating. Don't panic. Let's break it down.

-

First, you need 4 pieces of data:

Average Daily Sales (ADs)Average Lead Time (LT)Standard Deviation of Demand (σD)(Measures sales volatility. Use=STDEV.S()in Excel).Standard Deviation of Lead Time (σLT)(Measures shipping stability. Also use=STDEV.S()).

-

Calculate

σLTD:

σLTD = √[(Avg Lead Time × StDev of Demand²) + (Avg Daily Sales² × StDev of Lead Time²)]

Example:

- Average Daily Sales (ADs) = 50

- Average Lead Time (LT) = 10 days

- StDev of Demand (σD) = 15 (Sales are quite volatile)

- StDev of Lead Time (σLT) = 2 (Shipping is fairly consistent)

- We'll aim for a 95% service level, so our Z-score is 1.65.

Calculate σLTD:

σLTD = √[(10 × 15²) + (50² × 2²)]

σLTD = √[(10 × 225) + (2500 × 4)]

σLTD = √[2250 + 10000] = √12250 ≈ 110.68

Finally, the safety stock:

Safety Stock = 1.65 × 110.68 ≈ 183 units

Conclusion: To be 95% confident you won't stock out, you need to hold 183 units as safety stock.

Ditch the Complex Formulas: Get Your Safety Stock Strategy in One Click

Are you feeling a bit overwhelmed by now? Standard deviations, Z-scores, square roots...

Don't worry! That's exactly the problem I wanted to solve for you.

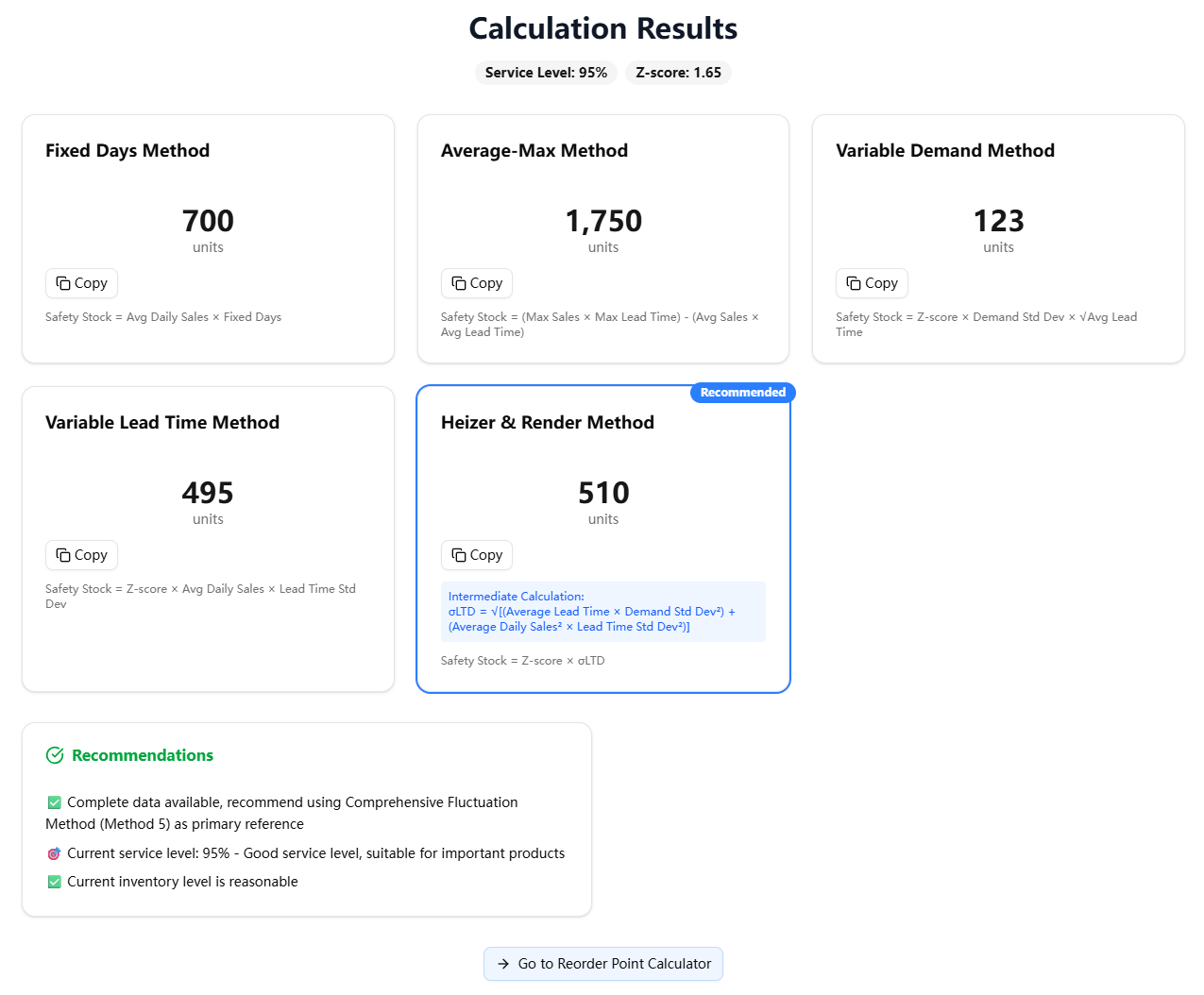

I've taken all of these complex formulas and packed them into one simple, easy-to-use online calculator. You just need to input your basic sales and lead time data, and it will calculate all the results for you in one second.

What the calculator does for you:

- ✅ No need to memorize any formulas.

- ✅ Just enter your basic business data.

- ✅ Automatically calculates safety stock using 5 different models.

- ✅ Completely free, use it now!

👉 Click Here to Try My Free Safety Stock Calculator Now! 👈

Final Thoughts

Safety stock isn't just a number; it should be integrated with your Reorder Point (ROP) and overall replenishment strategy.

Tools are here to support our decisions, but the final call still benefits from your operational experience. I hope this guide—and the calculator you're about to try—will become powerful weapons in your fight against inventory anxiety.

What's the biggest inventory headache you've ever faced? Share your story in the comments below!